The Future of Metal Fabrication: Innovation, Precision & Solutions

- administrator6325

- May 27, 2025

- 9 min read

Updated: Jun 6, 2025

The metal fabrication industry is undergoing a powerful transformation. What was once considered a traditional, labour-intensive trade has evolved into a highly technical, innovation-driven field that serves as the backbone of countless industries, from construction and agriculture to energy, transportation, and advanced manufacturing. In today’s competitive marketplace, businesses are seeking more than just parts or structural components; they’re demanding precision-engineered solutions that are efficient, cost-effective, and tailored to their exact specifications.

As industry standards grow more complex and project timelines tighten, the need for dependable, detail-oriented fabrication partners has never been greater. Customization is no longer a luxury, it’s a necessity. Companies across sectors are looking for metal fabrication firms that not only deliver exceptional craftsmanship but also bring strategic insight, engineering support, and streamlined production capabilities to the table.

At MAF Metal Alloy Fabrication, we’re proud to be at the forefront of this evolving landscape. With decades of hands-on experience and a passion for progress, we’ve built our reputation around excellence in both standard and custom fabrication services. From single-piece prototypes to full-scale industrial production, our goal is to deliver unmatched value and precision to every client, every time.

What sets MAF apart is our commitment to combining an old-school work ethic with next-generation technology. Our approach isn’t just about bending metal, it’s about shaping the future of fabrication by listening to our customers, investing in innovation, and delivering results that exceed expectations. Whether you're in agriculture, architecture, or industrial, our team is ready to transform your concepts into high-performing, real-world solutions.

In this blog, we’ll explore the changing face of metal fabrication and how MAF’s custom, customer-centric approach is helping businesses across North America overcome challenges, seize opportunities, and build with confidence.

The Evolution of Metal Fabrication Through Innovation & Technological Progress

Metal fabrication has a long and storied history, dating back thousands of years when early civilizations began working with copper, bronze, and later iron to create tools, weapons, and infrastructure. Over centuries, techniques advanced from hand-forging to blacksmithing, and eventually to industrial-scale production during the Industrial Revolution. What was once a craft honed through manual labour has evolved into a sophisticated, technology-enabled field central to modern manufacturing and infrastructure.

From Craftsmanship to Precision Engineering

In the early days, fabrication relied almost exclusively on manual processes and the artisan skill of the individual fabricator. Each piece was unique, often built by trial and error, and production volumes were low. As the demand for faster, more standardized manufacturing grew, so did the tools and techniques. By the late 19th and early 20th centuries, the introduction of machines like mechanical shears, punches, and rolling equipment transformed how metal parts were shaped and assembled.

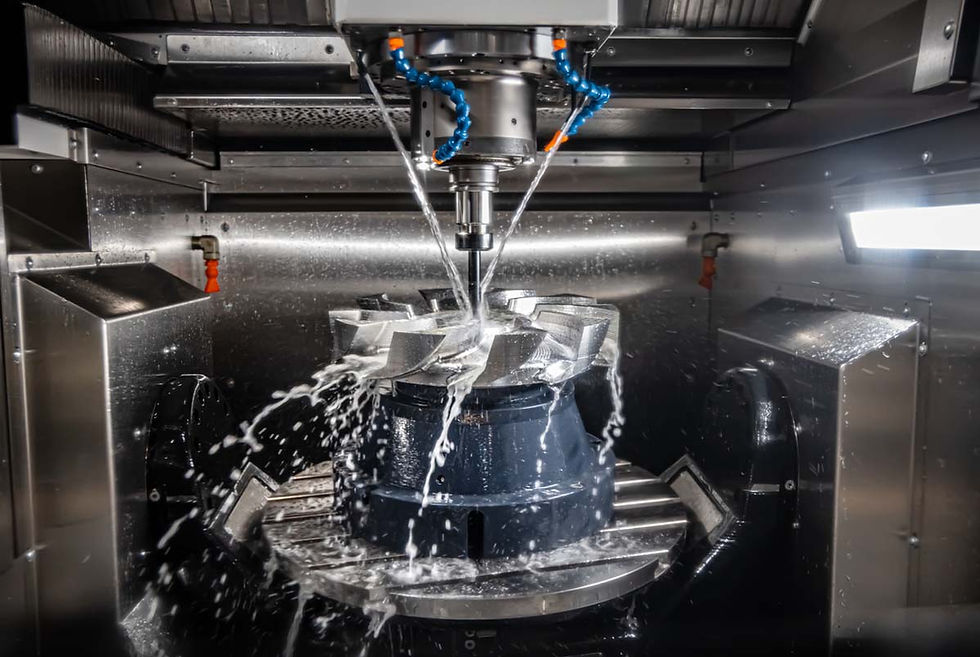

The mid-20th century saw the rise of automated welding, computer-assisted machining, and the integration of hydraulic systems, allowing for faster production and greater accuracy. Today, the industry leverages cutting-edge technologies like CNC (Computer Numerical Control) machines, laser cutting, plasma cutting, waterjet systems, and 3D modelling to achieve levels of precision and consistency once thought impossible.

Digital Transformation in Fabrication

The digital revolution has propelled metal fabrication even further. With advancements in CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and Industry 4.0 technologies, fabricators now have access to real-time data, predictive analytics, and virtual prototyping. These tools empower engineers and machinists to design, test, and optimize components before a single cut is made.

Cloud-based file sharing and remote collaboration tools also enable clients and engineers to work closely, regardless of geography, to streamline design revisions, reduce miscommunication, and accelerate timelines.

The Rise of Custom Fabrication

As industries become more specialized, the demand for custom metal fabrication has increased significantly. Off-the-shelf solutions often fall short when dealing with unique applications, tight spaces, or complex geometries. That’s where companies like MAF Metal Alloy Fabrication come in. Our expertise in custom design, rapid prototyping, and specialty welding allows us to support clients with tailor-made solutions that maximize performance and minimize downtime.

Custom fabrication isn’t just about cutting and welding to spec, it’s about problem-solving, innovation, and understanding how each component fits into a larger system. Whether it’s a one-of-a-kind architectural installation or a heavy-duty agricultural machine frame, MAF has the expertise to bring concepts to life.

Sustainability & Smarter Fabrication

Another key factor shaping the future of fabrication is sustainability. Modern clients are increasingly looking for partners who can support greener initiatives through material efficiency, waste reduction, and energy-conscious manufacturing. By embracing smarter cutting techniques, recycling scrap metal, and using energy-efficient equipment, MAF ensures both high performance and environmental responsibility.

We also work with customers to optimize material selection, recommending alloys and finishes that improve durability, reduce maintenance, and extend the lifespan of finished products, all while aligning with their sustainability goals.

What Sets MAF Metal Alloy Fabrication Apart

In today’s competitive industrial landscape, choosing the right metal fabrication partner can be the difference between success and setback. At MAF Metal Alloy Fabrication, we understand that our clients need more than just cut-and-weld services, they need a strategic partner who brings expertise, innovation, and consistency to every project. So, what truly sets us apart in the world of custom metal fabrication and machining?

1. Customer-First Philosophy

From the very beginning, MAF has embraced a customer-centric approach. We recognize that every project is unique, with specific performance, budgetary, and timing requirements. That’s why we take the time to fully understand your goals, challenges, and expectations. Our process is collaborative and transparent, ensuring our clients are informed and involved at every stage, from initial concept to final inspection.

At MAF, communication is more than a value, it’s a commitment. Whether we’re working with a small business or a multinational corporation, we offer the same personalized service and proactive problem-solving that has earned us long-term relationships across multiple industries.

2. Full-Service Capabilities Under One Roof

Many fabricators specialize in only one or two core services, often requiring customers to coordinate with multiple vendors. MAF simplifies the process by offering a comprehensive suite of services, all in-house. Our facility is equipped to handle:

Custom Metal Fabrication

CNC Machining

Welding & Assembly

Prototyping & Design Support

Surface Treatments & Finishing

Value-Added Services & Logistics

This all-inclusive model reduces lead times, minimizes errors, and ensures consistent quality throughout the project lifecycle. It also allows us to adapt quickly to change orders or evolving project requirements.

3. Advanced Technology & Equipment

To stay ahead in an ever-evolving industry, we continually invest in cutting-edge fabrication equipment and software. Our production floor features high-performance CNC machines, precision plasma and laser cutters, MIG/TIG welding stations, and state-of-the-art measuring tools for tight-tolerance quality control.

On the digital side, our engineering team uses the latest CAD/CAM programs to create and simulate designs with pinpoint accuracy. These technologies allow us to optimize materials, streamline production, and detect potential issues long before they affect delivery schedules.

4. Cross-Industry Expertise

MAF Metal Alloy Fabrication has built a reputation for serving a wide range of industries with highly specialized needs. Our team brings decades of combined experience in:

Agriculture: Robust components built to withstand tough outdoor conditions

Architecture: Custom structures, railings, and decorative features with aesthetic appeal

Industrial Manufacturing: Heavy-duty frames, guards, brackets, and enclosures built for performance

Oil & Gas: High-strength, corrosion-resistant parts for critical applications

Transportation & Logistics: Durable, lightweight metal components for efficient mobility solutions

Our deep understanding of each industry’s requirements allows us to recommend the best materials, fabrication methods, and design approaches to ensure optimal performance and longevity.

5. Skilled Craftsmen & Engineering Talent

Behind every successful project is a team of dedicated professionals. At MAF, our fabricators, machinists, and engineers are not only highly skilled but also passionate about their work. Every weld, cut, and polish is executed with attention to detail and pride in craftsmanship.

We also foster continuous learning and development, ensuring our team stays current with the latest fabrication techniques and industry best practices. This emphasis on training results in higher precision, fewer defects, and better overall value for our clients.

6. Commitment to Quality & Safety

Quality is not a checkbox at MAF, it’s a culture. We have rigorous inspection protocols in place at every stage of the fabrication process. From material verification and dimensional checks to final assembly testing, our team ensures that your parts meet the highest standards.

Safety is equally critical. Our workplace is governed by strict safety policies, regularly audited practices, and training programs that protect both our employees and your product integrity.

Future-Forward, Our Vision for Growth & Innovation

As MAF Metal Alloy Fabrication looks ahead, one thing is clear: the future of metal fabrication is being shaped by innovation, adaptability, and a deep understanding of our clients' evolving needs. Our journey so far has been defined by precision craftsmanship, strong relationships, and consistent performance, but we’re just getting started.

In this final chapter, we explore our forward-thinking strategies, technology investments, and unwavering commitment to staying ahead of the curve in an ever-changing industry.

1. Embracing Smart Manufacturing Technologies

At MAF, we’re actively adopting smart manufacturing practices to enhance efficiency, accuracy, and real-time decision-making. By leveraging data-driven systems and automation, we’re streamlining production and reducing downtime while maintaining our uncompromising quality standards.

Our future-focused technologies include:

IoT-Enabled Equipment: Machines that communicate performance and maintenance data in real time.

Automated CNC Machining & Robotics: Increasing precision while minimizing human error and lead time.

Cloud-Based Project Management Tools: Enabling better collaboration and workflow tracking across departments and client interfaces.

AI-Assisted Design Software: Accelerating design iterations while reducing material waste and cost.

These tools aren’t just about keeping up, they’re about creating smarter workflows and better outcomes for our clients.

2. Investing in Our People

No matter how advanced our equipment becomes, it’s the people behind the machines who make MAF what it is. That’s why we’re committed to ongoing education, training, and mentorship programs that foster professional development across all departments, from the shop floor to the design office.

We’re building the workforce of tomorrow by:

Providing continuous training in welding certifications, machine operation, and CAD/CAM technologies.

Encouraging cross-training so team members gain diverse skills and career flexibility.

Mentoring young talent through apprenticeship programs and community outreach.

Fostering a culture of collaboration, curiosity, and leadership.

As we grow, our workforce will grow with us, stronger, smarter, and more capable than ever.

3. Expanding Capabilities & Capacity

With increasing demand for custom fabrication and value-added machining across industries, MAF is strategically scaling operations to meet the challenge. Our growth plan includes facility upgrades, additional equipment, and expanded service offerings that allow us to take on larger, more complex projects without sacrificing quality or turnaround times.

What this means for our customers:

Higher throughput for time-sensitive production runs

Larger project capacity and storage capabilities

Enhanced in-house capabilities to reduce reliance on subcontractors

New service additions to streamline the customer experience

We are committed to growth that enhances, not compromises, our service quality.

4. Strengthening Environmental Responsibility

Sustainability is more than a buzzword, it’s a responsibility. MAF is actively working toward reducing our environmental impact by implementing greener practices in every area of our operation. From recycling scrap metal to investing in energy-efficient systems, we’re taking steps to reduce waste and contribute to a cleaner, more sustainable future.

Our environmental initiatives include:

Recycling programs for all metals and materials

Investing in low-emission, energy-efficient machinery

Digital workflows to reduce paper waste

Lean manufacturing practices that minimize excess and scrap

Exploring partnerships with suppliers who share our sustainability goals

We believe great fabrication doesn’t have to come at the environment’s expense.

5. Diversifying Into New Markets

While we’ve built a solid foundation in the agricultural, architectural, and industrial sectors, MAF is exploring growth in emerging markets that need custom fabrication solutions. As new technologies and infrastructure demands evolve, we’re positioning ourselves as a flexible, forward-thinking partner ready to support the next generation of innovations.

Target growth sectors include:

Clean energy and renewable infrastructure

EV charging station components and structures

Modular building and prefab construction

Specialized medical and laboratory equipment housing

Aerospace and precision technology

By applying our core strengths to new applications, we’re ensuring the future of MAF is as diverse as it is dynamic.

6. Building a National & Global Presence

While proudly rooted in Canada, MAF has ambitions beyond our current borders. With expanding capabilities, scalable production, and a reputation for dependable quality, we’re seeking new partnerships across North America and beyond.

Our goals for geographic growth:

Establish new regional distribution and service centers

Form strategic alliances with complementary manufacturers

Develop export capabilities for international markets

Expand digital reach through targeted marketing and online quoting systems

Whether across the province or across the continent, MAF aims to be a name synonymous with quality and reliability.

7. Innovating with Our Clients

The future isn't something we build alone. It’s something we create alongside the innovators, engineers, builders, and problem-solvers we serve. That’s why MAF is building stronger partnerships with clients through collaborative design sessions, prototyping labs, and joint development initiatives.

How we collaborate on innovation:

Co-developing prototypes based on unique client specifications

Iterating designs quickly with our CAD/CAM software and rapid manufacturing tools

Sharing insights and feedback through open communication

Offering technical guidance to improve function, form, and manufacturability

We don’t just fabricate parts, we help bring ideas to life.

8. Staying Grounded in Our Values

As we evolve, we’re grounded by the values that brought us this far: integrity, precision, service, and hard work. These aren’t just words, they’re the foundation of every weld, every cut, every conversation, and every commitment we make.

We will always:

Prioritize our clients’ success

Invest in our people and equipment

Strive for better every day

Deliver what we promise

Stand behind the quality of our work

The tools may change, but our mission stays the same: to be your most trusted partner in metal fabrication.

Looking Ahead with Confidence

MAF Metal Alloy Fabrication is not just preparing for the future, we’re actively building it. With bold investments, visionary leadership, and a relentless focus on quality, we’re ready to meet the challenges of tomorrow with the same precision and pride we bring to every project today.