Exploring Machining Services at MAF Metal Alloy Fabrication

- Jul 24, 2025

- 8 min read

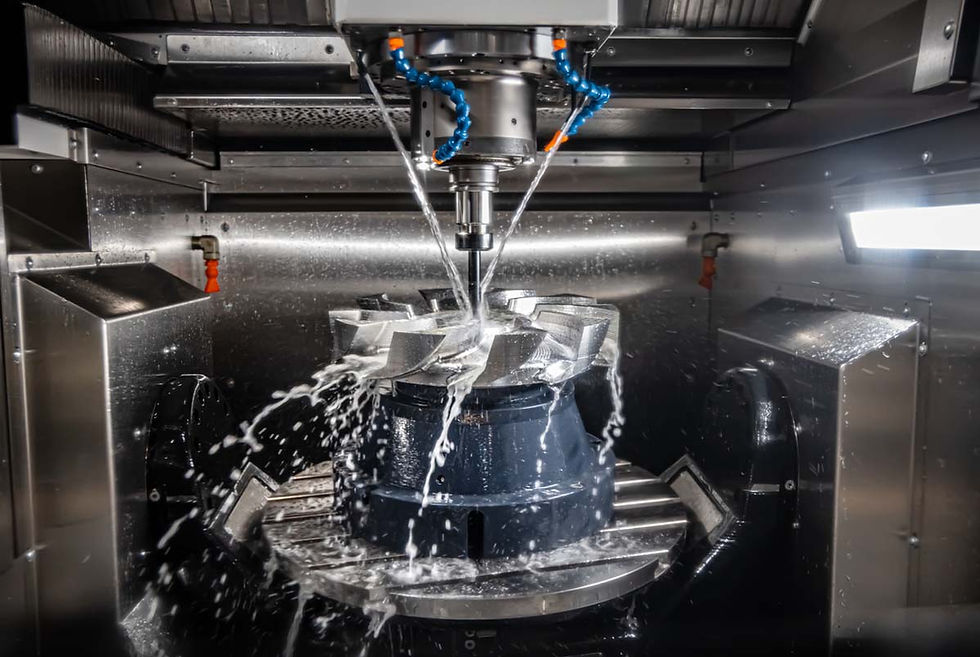

In the world of custom metal fabrication, machining plays a central role in shaping raw materials into finished components with exceptional accuracy and reliability. At MAF Metal Alloy Fabrication, our machining capabilities are an integral part of how we bring innovative architectural and industrial designs to life. From detailed parts for architectural features to intricate components for larger metal structures, machining is where ideas are sculpted into precision.

This blog explores the full scope of MAF’s machining services, what machining is, why it matters, the technologies we use, and how our expertise ensures high-performance results. Whether you're a general contractor, architect, designer, or business owner seeking custom metal solutions, this deep dive into machining will help you understand how MAF turns solid metal into stunning, functional works of art.

What Is Machining? Understanding the Precision Process Behind Metal Fabrication

Machining is the process of shaping metal and other rigid materials using controlled material removal. This can involve a wide range of techniques, including drilling, turning, milling, and grinding. Machining is essential in producing everything from the smallest mechanical parts to large-scale architectural elements.

At MAF, we utilize modern machining tools and CNC (Computer Numerical Control) equipment that allow for precise, repeatable, and highly accurate cuts, shapes, and finishes. Our team of skilled machinists work across a wide variety of metals, such as aluminum, stainless steel, and brass, tailoring each project to meet specific functional and aesthetic requirements.

Unlike cutting methods that use heat or water, machining relies on physical tools to remove material, which is ideal for parts that require high dimensional accuracy and clean finishes. For architectural and industrial clients alike, machining provides the detail and customization necessary to make designs practical and buildable.

Types of Machining at MAF

Our machining services include a diverse array of methods, each suited for particular types of components and materials. Some of the most commonly used machining processes at MAF include:

Milling – This technique uses rotating cutting tools to remove material. Milling is ideal for creating flat surfaces, slots, and complex 3D contours.

Turning – Performed on a lathe, turning rotates the workpiece while a cutting tool shapes it. It’s perfect for producing cylindrical parts like shafts, tubes, and threaded pieces.

Drilling – One of the most basic yet essential processes, drilling creates clean, accurate holes for fasteners, fixtures, and other components.

Tapping & Threading – This allows us to add functional threaded holes or surfaces for bolts and screws, which are often required in both architectural and mechanical applications.

Surface Finishing – Our machining process doesn’t end with shaping. We offer deburring, polishing, and other finishing techniques to ensure each part looks as good as it functions.

Each method is chosen based on the specific tolerances, finishes, and functions required for the part. MAF's team works collaboratively with clients to determine the best machining path for every project.

Why Machining Matters in Architectural Metal Fabrication

In architectural applications, machining provides the precision necessary to bring creative visions to life without sacrificing structural integrity or performance. Many architectural metal features, like custom cladding systems, bracketry, handrails, or decorative grilles, require parts that must fit seamlessly into other building components.

For example, a custom-built metal screen in a hotel lobby may look simple from the outside, but its internal structure relies on finely machined brackets and connectors to maintain strength and symmetry. MAF’s machining capabilities allow these hidden parts to be just as flawless as the visible ones.

Machining also helps with repeatability. If your project includes multiple identical units, such as decorative lighting housings, balusters, or mounting plates, our CNC machining tools can reproduce each component with micron-level accuracy.

Industries We Serve With Machining Services

MAF’s machining services support a broad spectrum of industries. Here’s how machining makes a difference across different sectors:

Architecture & Design

Architectural clients turn to MAF for precision-machined components that blend seamlessly into high-end designs. Whether it’s a custom sign bracket or a support structure for a large-scale art installation, machining enables complex forms with reliable connections.

Commercial Construction

Construction professionals rely on our machining capabilities for fixtures, anchor systems, and custom support structures. These parts must meet strict specifications for performance and safety.

Retail & Hospitality

Retail environments often use decorative metal elements to reinforce brand identity. Machining helps us produce clean, polished, and consistent components for signage, display fixtures, lighting, and interior accents.

Office Spaces

Corporate interiors benefit from machined details in reception areas, wayfinding systems, and branded architectural features. High-end finishes and precision fits help elevate the entire space.

Custom Projects

Every now and then, a project doesn’t fit into a conventional category. MAF’s machining services offer the flexibility to take on one-of-a-kind designs that require custom-built precision parts, no matter the application.

Materials We Machine

At MAF, we work with a wide range of materials to suit the aesthetic and functional demands of your project. Some of the most common metals we machine include:

Aluminum – Lightweight and corrosion-resistant, great for architectural elements.

Stainless Steel – Durable and elegant, ideal for public spaces and high-touch environments.

Brass – Perfect for accents, signage, and design-forward applications.

Carbon Steel – Strong and reliable, often used in structural or mechanical parts.

Each material comes with its own machining characteristics, and our team has deep experience in managing tooling, speed, and cutting strategies for optimal results.

Precision & Consistency: Why CNC Machining Sets MAF Apart

One of the core strengths of MAF’s machining department is our investment in CNC machining technology. CNC stands for Computer Numerical Control, which means the machinery is operated via software that controls tool movement with exacting precision.

This results in:

High Repeatability – Essential for multi-unit runs or modular construction.

Tight Tolerances – Perfect for parts that must fit together seamlessly.

Faster Turnarounds – More efficient production keeps timelines on track.

CNC machining also integrates well with our design and drafting tools, allowing for seamless file transfers from digital drawings to physical fabrication. Whether you’re working with DWG files, STEP files, or even hand-drawn sketches, we can digitize and execute with extreme accuracy.

Customization & Collaboration

At MAF Metal Alloy Fabrication, customization isn’t just a service; it’s a mindset that shapes every step of our machining process. We recognize that no two projects are the same, and that's why collaboration lies at the heart of how we approach machining. From initial concept to final product, we work directly with architects, designers, engineers, and contractors to ensure that every part is built to meet both visual and technical expectations.

Our customization process often starts well before the machining begins. Early in the design phase, our team offers value-engineering insights, helping clients choose the right material, finish, and machining method to balance budget, performance, and appearance. We can also recommend alternate fastening or assembly techniques that improve installation without compromising design.

Using detailed CAD models, 3D renderings, and shop drawings, we map out every facet of your project to avoid surprises during fabrication. Once we move to machining, our CNC equipment and skilled machinists bring these designs to life with exceptional precision, cutting, drilling, tapping, and finishing each component to meet exact specifications. Whether you're producing a one-off feature or a series of repeating parts, we ensure consistency across every piece.

This hands-on approach is particularly valuable for projects that involve tight timelines, unique constraints, or innovative concepts. We often serve as a creative problem-solving partner, working alongside clients to prototype components, fine-tune tolerances, and refine designs in real-time. For example, if a designer brings us an idea for a custom perforated metal screen with integrated lighting, we’ll help determine the ideal cut pattern, support structure, and access points, all while making sure it meets code and installation needs.

Our collaborative approach also streamlines communication between disciplines. Because we’ve worked closely with a wide range of professionals, from millwork shops and general contractors to lighting designers and signage companies, we understand how to integrate our machined components into broader project scopes without conflict or delay.

At the end of the day, our goal is to be more than just your fabricator; we aim to be your design ally. Through transparent communication, problem-solving, and technical know-how, MAF ensures that each machined component is an exact match to your creative vision and practical needs.

Real-World Applications: Machining Projects by MAF

Here are just a few examples of how MAF’s machining services have helped bring bold ideas to life:

Southcentre Mall Railings – Machined metal connection points ensured that sleek glass and metal railings were as secure as they were stylish.

PCL Construction Office Elevator Panelling – Precision-machined brackets allowed large metal sheets to be installed flush within an elevator environment where space was limited.

Custom Metal Directory at U of C MacEwan Hall – Intricate lettering and mounting features were all machined to exacting specifications for this high-traffic student center.

Corporate Signage Systems – From logos to backlit metal panels, our machining tools make brand stories shine, literally and figuratively.

Sustainability Through Precision

Sustainability is often thought of in terms of materials or energy consumption, but at MAF, precision itself is a powerful sustainability tool. Our machining services are designed not only to produce flawless results but to do so with minimal waste, smarter resource use, and long-term efficiency in mind.

Every machined part we produce is cut with intent. Our CNC-controlled machines are programmed to optimize material layouts, ensuring the highest possible yield from every sheet or bar of metal. This reduces off-cuts and scrap waste, conserving valuable raw materials and lowering our environmental impact. For complex jobs, we even run digital simulations ahead of cutting to ensure efficient tool paths and prevent unnecessary rework.

Additionally, many of the metals we use, such as aluminum, stainless steel, and carbon steel, are recyclable, meaning any residual material can be recovered and reprocessed instead of ending up in a landfill. In fact, we partner with certified metal recyclers to ensure that even our offcuts are put back into the supply chain responsibly.

Sustainability also comes from longevity. Machined parts that are built with tight tolerances and proper finishes are more durable, require fewer repairs, and are less likely to be replaced over time. That means fewer resources are used in the long run, something especially important in high-traffic environments like commercial lobbies, retail stores, or public institutions.

Beyond the machining process itself, our team is focused on sustainable practices across our fabrication shop. This includes responsibly sourcing materials, reducing packaging waste, and using eco-conscious cleaning and finishing solutions wherever possible. It’s part of our broader mission to operate not just as a top-tier metal fabricator, but as a responsible business partner in the built environment.

For clients who prioritize green building standards, such as LEED, WELL, or BOMA BEST, our precise machining capabilities support sustainable architecture by enabling durable, adaptable, and material-efficient designs. Whether it’s a modular metal feature that can be disassembled and reused, or a custom bracket designed for minimal hardware, we help build spaces that are not only visually compelling but environmentally thoughtful.

At MAF, sustainability is baked into every detail, and it starts with the precision and discipline of our machining work.

Conclusion: Why Machining Matters at MAF

Machining is more than just another service we offer; it's a cornerstone of our commitment to precision, quality, and customer collaboration. It ensures that every part we fabricate not only fits but functions, enhancing the final experience of your space, structure, or product.

From office towers to luxury hotels, from retail stores to public installations, MAF’s machining capabilities make sure that every metal element meets the highest standards of performance and appearance.

Whether you’re designing a branded architectural feature, installing a new set of interior fixtures, or developing a unique piece of functional art, our machining services are ready to turn your ideas into reality, with precision in every cut.