Exploring Deburring, Brushing, & Finishing Services at MAF

- Aug 7, 2025

- 6 min read

In the world of metal fabrication, the difference between good and exceptional often lies in the finishing touches. At MAF Metal Alloy Fabrication, we understand that it’s not just about cutting and shaping metal; it’s about refining it. Deburring, brushing, and finishing are critical post-fabrication processes that elevate the quality, performance, and aesthetic of every component that leaves our facility. These processes aren’t optional add-ons; they are essential steps in delivering safe, durable, and visually flawless products. Whether we're working on complex architectural panels, signage, or structural components, we treat finishing with the same care and precision as cutting or welding. In this blog, we’ll take a deep dive into what these finishing services involve, why they matter, and how MAF continues to push the boundaries of quality and precision in every finished piece.

What Is Deburring? Understanding the First Step in Metal Surface Perfection

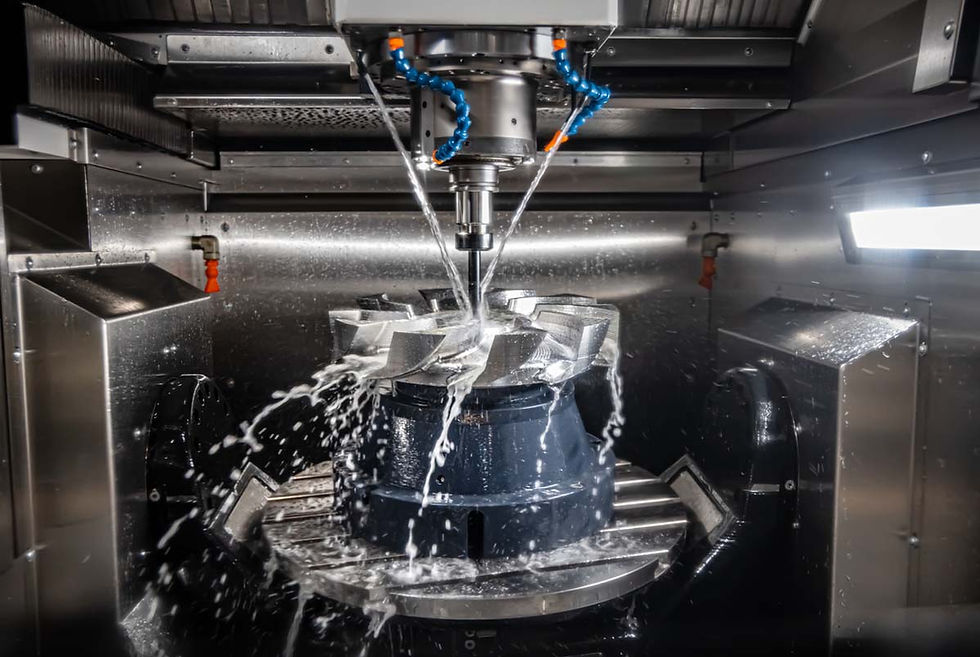

Deburring is the process of removing small imperfections, such as sharp edges, burrs, or protrusions, that remain after cutting, drilling, milling, or other metalworking processes. These tiny defects may seem minor, but they can pose serious issues, including safety hazards, poor fit, and even premature wear or failure of mechanical components.

At MAF, we use a variety of mechanical and manual deburring techniques to ensure every component is smoothed to meet exacting standards. Depending on the material and application, we may use grinding wheels, abrasive belts, hand tools, or vibratory deburring machines. Our trained specialists assess each piece to determine the most effective deburring method, ensuring that every part is free from sharp edges and ready for safe, functional use.

Beyond functionality, deburring also enhances aesthetics, making components look more refined and professional. It’s a critical quality assurance step that reflects our commitment to detail, safety, and client satisfaction.

What Is Brushing in Metal Fabrication?

Deburring is the process of removing small imperfections, such as sharp edges, burrs, or protrusions, that remain after cutting, drilling, milling, or other metalworking processes. These tiny defects may seem minor, but they can pose serious issues, including safety hazards, poor fit, and even premature wear or failure of mechanical components.

At MAF, we use a variety of mechanical and manual deburring techniques to ensure every component is smoothed to meet exacting standards. Depending on the material and application, we may use grinding wheels, abrasive belts, hand tools, or vibratory deburring machines. Our trained specialists assess each piece to determine the most effective deburring method, ensuring that every part is free from sharp edges and ready for safe, functional use.

Beyond functionality, deburring also enhances aesthetics, making components look more refined and professional. It’s a critical quality assurance step that reflects our commitment to detail, safety, and client satisfaction.

What Is Finishing in Metal Fabrication?

“Finishing” in metal fabrication is a broad term that encompasses all the final processes applied to a metal product to improve its appearance, durability, corrosion resistance, and functionality. These can include deburring and brushing, but also extend to polishing, coating, anodizing, sandblasting, painting, and even laser engraving.

At MAF, finishing isn’t a one-size-fits-all process. We consult with clients to determine the ideal finish based on performance requirements, environmental conditions, and visual expectations. For example, architectural projects may call for a high-polish mirror finish, while industrial components may require powder coating for corrosion resistance.

Our team leverages decades of combined experience and cutting-edge equipment to apply finishes with consistent quality across all parts. We understand how each finishing process affects the metal’s properties and work to strike the right balance between form and function.

Why Finishing Processes Matter

While cutting, bending, and welding get much of the spotlight in metal fabrication, finishing is the unsung hero that defines the final quality of a part or product. A well-executed finish ensures:

Safety: Smooth, deburred edges prevent injury during handling and use.

Durability: Finishes such as powder coating or anodizing add protection against corrosion and wear.

Aesthetics: Whether the goal is industrial ruggedness or architectural elegance, finishing defines the visual appeal of metalwork.

Performance: In many applications, surface finish affects how a component fits or interacts with other parts.

At MAF, finishing is integrated into our quality control process. Every product is evaluated not just for structural accuracy but also for visual and tactile quality. We see finishing as the bridge between fabrication and real-world application, it’s where raw metal transforms into a market-ready solution.

Tools & Technology in Deburring, Brushing, and Finishing

The tools and technology used in finishing processes have evolved dramatically in recent years, and MAF has remained at the forefront. Our facility is equipped with state-of-the-art machinery that allows for precision and repeatability across all finishing services.

For deburring, we utilize:

Vibratory tumblers for small batch components

Handheld rotary tools for precision work

Belt sanders and deburring wheels for larger surfaces

For brushing, we offer:

Automated brushing machines with variable speeds and pressure settings

Manual brushing stations for delicate or irregular parts

Brushing with different grit levels depending on finish requirements

For finishing, we implement:

Powder coating booths and ovens

Surface polishers and buffing equipment

Surface treatment tanks for chemical finishing or anodizing

Technology doesn’t replace skill; it enhances it. Our trained technicians and artisans bring deep knowledge to each step of the process, combining hands-on expertise with machine precision. This approach ensures a finish that not only meets expectations but exceeds them.

Materials We Work With

Different materials demand different finishing methods. At MAF, we tailor our approach based on the metal being used. Common materials include:

Aluminum: Often brushed or anodized for modern, corrosion-resistant finishes.

Stainless Steel: Brushed or polished to varying degrees based on application.

Mild Steel: Frequently powder coated for protective and decorative purposes.

Brass & Copper: Require gentle polishing or coating to retain colour and reduce oxidation.

Each material has its own finishing characteristics, and our team is well-versed in maximizing results across a diverse range of metals.

Applications Across Industries

Our finishing services are used in projects spanning multiple sectors:

Architectural Metalwork: Brushed stainless steel railings, decorative panels, and stair systems.

Commercial Interiors: Polished elevator panels, finished signage, and brushed metal counters.

Industrial Components: Deburred and coated machine parts for safety and longevity.

Hospitality & Retail: Custom-finished installations that match brand aesthetics and high-traffic durability.

From malls and airports to educational institutions and public art, MAF’s finished products can be seen throughout Calgary and beyond.

Real-World Projects That Reflect Our Craft

Some standout projects that showcase our deburring, brushing, and finishing expertise include:

Southcentre Mall (Calgary): Stainless steel railings and elevator elements, all meticulously brushed and finished for durability and design appeal.

Cowboys Casino (Calgary Stampede Grounds): Custom-finished metal signage and railing work that reflect the energy of the venue while meeting safety standards.

CORE Shopping Centre: Interior architectural finishes that contribute to the upscale retail experience.

University of Calgary: Custom directional signage and display panels, finished to endure constant public interaction.

These projects speak not only to our technical capabilities but to our understanding of how finishing affects perception and performance.

Customization & Collaboration in Every Project

We don’t believe in one-size-fits-all solutions. Our clients have unique needs, and our job is to bring their vision to life. That’s why we offer customization at every stage of the finishing process. Whether a project requires a specific grit of brush finish, a vibrant colour powder coat, or a precise level of smoothness, we collaborate to deliver exactly what’s needed.

Our team works closely with architects, contractors, designers, and manufacturers to ensure alignment between concept and outcome. From mock-ups to final installation, MAF is your partner in precision.

Sustainability Through Smart Finishing

Our approach to surface finishing doesn’t just focus on performance; it also considers the planet. MAF incorporates eco-conscious practices like:

Using low-VOC coatings

Recycling metal scrap from brushing and grinding

Utilizing energy-efficient finishing equipment

Reducing chemical waste through closed-loop systems

By making sustainability part of our core processes, we help our clients meet their own environmental goals while contributing to a cleaner, more responsible industry.

The MAF Difference in Metal Finishing

What sets MAF apart is not just our state-of-the-art tools or skilled technicians, it’s our philosophy of excellence. We see finishing as the defining moment in a project’s lifecycle, the last chance to deliver the quality that clients deserve. Our obsession with detail, safety, and longevity translates to work that speaks for itself.

We don’t rush the final steps; we elevate them. Every finish we apply is intentional, thoughtful, and expertly executed.

Conclusion: More Than Just a Surface Treatment

At MAF Metal Alloy Fabrication, our dedication to quality doesn’t stop when the welding arc cools or the cutting machine turns off. It continues through every step of the finishing process, from removing burrs and rough edges to creating beautiful, protective finishes that extend the life and appeal of every component.

Deburring, brushing, and finishing may be the final steps, but they are far from an afterthought. They are part of our holistic approach to metal fabrication that prioritizes safety, precision, and craftsmanship at every stage. Whether you're designing a high-end architectural feature or a complex mechanical part, you can trust MAF to deliver not just a functional product, but a finished one.

Let’s bring your next project to life with a finish that stands out and performs even better.