From Vision to Value: MAF’s Precision Fabrication with Purpose

- administrator6325

- May 27, 2025

- 7 min read

Updated: Jun 6, 2025

At MAF Metal Alloy Fabrication, our work is more than just metalwork, it’s a commitment to precision, partnership, and long-term value. Whether you're designing a new product, retrofitting equipment, or scaling up production, the journey from concept to completion requires more than technical capability. It demands a well-defined process, a team of experienced problem-solvers, and a dedication to quality that never cuts corners.

In this blog, we’ll take you behind the scenes of how we bring your ideas to life through our proven fabrication process, and explore what truly sets MAF apart from the rest. From discovery and design to delivery and support, here’s how we build better outcomes, one project at a time.

Our Proven Process: From Initial Concepts to Complete Fabricated Solutions

At MAF Metal Alloy Fabrication, we believe that the foundation of exceptional results lies in a clearly defined, collaborative, and efficient process. Whether you're launching a new project, improving an existing system, or looking for a reliable long-term fabrication partner, our proven workflow ensures every detail is aligned with your goals from the very beginning.

Here’s a closer look at how we bring your vision to life, step by step.

1. Discovery & Consultation

Every project starts with a conversation. We take the time to understand your objectives, challenges, and expectations. During the discovery phase, our team works with you to gather critical information about the application, material requirements, performance demands, timelines, and budget.

What’s involved:

Initial client meeting or site visit

Review of specifications or drawings

Clarification of industry regulations or compliance needs

Identifying opportunities to improve functionality or efficiency

Offering early insights on materials and processes

This phase is all about partnership. We’re not just fabricators, we’re problem solvers dedicated to building the most effective solution for your unique needs.

2. Design & Engineering

Once your requirements are clear, our in-house design and engineering team begins developing a detailed plan. We use advanced CAD software to draft custom solutions that maximize strength, efficiency, and manufacturability.

Our design process includes:

2D/3D CAD modeling

Material selection based on performance and cost

Tolerance analysis

Structural evaluations for load-bearing applications

Design for manufacturability and assembly (DFMA)

We work closely with you throughout the design phase to ensure all expectations are met. Need changes? We’re agile and ready to revise until every element is just right.

3. Material Procurement

Once the design is approved, we move swiftly into material sourcing. Thanks to our trusted supplier network and extensive inventory of steel, aluminum, and specialty alloys, we can secure the highest quality materials at competitive prices, without unnecessary delays.

What sets us apart:

Access to a wide range of metals and finishes

Certified materials for traceability and compliance

Special orders for hard-to-find or niche materials

Bulk purchasing power to reduce costs

Environmentally responsible sourcing options

We match materials to your specs to ensure performance, longevity, and cost-efficiency in every project.

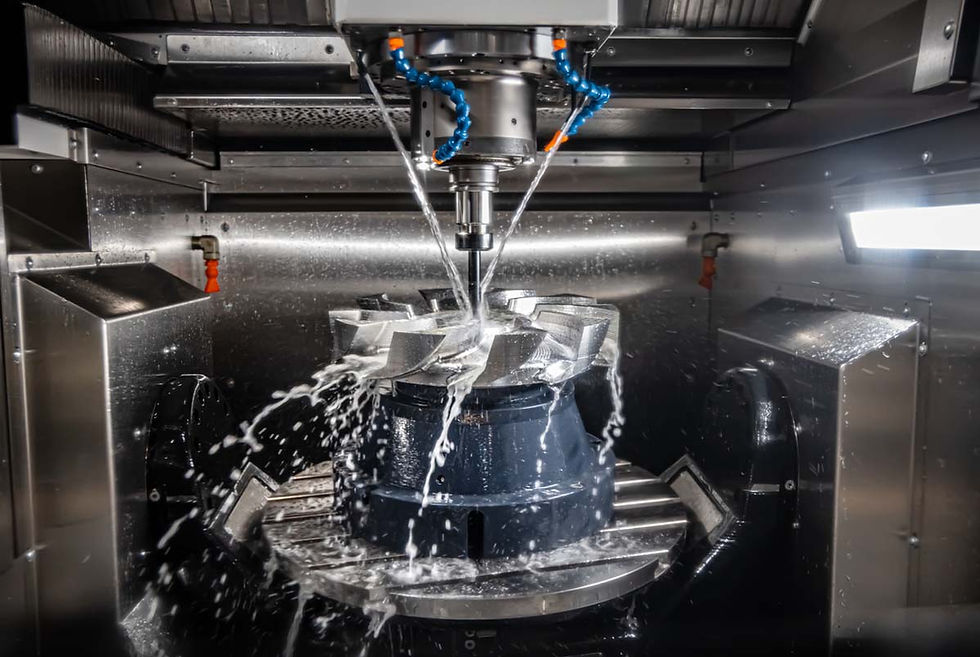

4. Fabrication & Machining

This is where the real craftsmanship begins. Our skilled fabricators and machinists bring your design to life with extreme precision and care. From cutting and welding to CNC machining and forming, our facility is equipped with state-of-the-art tools and technology.

Capabilities include:

Laser cutting and plasma cutting

MIG, TIG, and stick welding

Brake forming and bending

CNC milling and turning

Drilling, tapping, and punching

Custom assemblies and subassemblies

Every step of the fabrication process is executed under strict quality control measures to ensure the final product meets your expectations and our high standards.

5. Finishing & Surface Treatments

The finish is more than just appearance, it impacts corrosion resistance, durability, cleanliness, and even safety. That’s why we offer a full range of finishing services, either in-house or through our network of trusted partners.

Finishing options include:

Powder coating

Sandblasting and bead blasting

Anodizing and passivation

Galvanizing

Painting and plating

Polishing and brushing for stainless applications

We help you select the right finish for your environment, brand, and performance needs.

6. Quality Assurance & Testing

At MAF, quality is non-negotiable. Every product goes through a thorough inspection process to ensure it meets dimensional accuracy, material specs, weld integrity, and visual standards.

Quality procedures may include:

Visual inspection

Dimensional verification

Weld testing (visual, magnetic particle, or dye penetrant)

Fit and function checks

Documentation and reporting for compliance

For industries like oil and gas, energy, or food processing, we also offer traceability and certifications to meet regulatory standards.

7. Packaging, Delivery & Installation

Once your components pass our rigorous quality control checks, we prepare them for delivery. Our team ensures that every part is securely packed, labelled, and protected to prevent damage during transit.

We offer:

Custom packaging solutions

Palletizing and labelling

Local and regional delivery options

Freight coordination

On-site installation or assembly (available on request)

We don’t consider the job done until the parts are in your hands, functioning as expected, or better.

8. Post-Project Support

Our commitment doesn’t end when the project is complete. Whether you need additional parts, adjustments, or future modifications, we’re here to help. As your long-term partner, we offer maintenance, re-fabrication, and consulting services as your needs evolve.

Continued support includes:

Technical consultations

Design updates and rework

Replacement parts or upgrades

Maintenance recommendations

Rapid response for urgent repairs

When you choose MAF, you're choosing a team that stands behind every weld, cut, and finish, well beyond project completion.

The MAF Difference: What Sets Us Apart

In a competitive industry where precision, speed, and reliability are everything, MAF Metal Alloy Fabrication stands out, not just for what we do, but for how we do it. Our clients span diverse industries, but they all rely on the same thing: confidence. Confidence that their job will be done right the first time. Confidence that their deadlines will be met. Confidence that they’re partnering with a team that brings value at every step. Here’s what makes The MAF Difference:

1. A Customer-First Philosophy

At MAF, the customer always comes first. We understand that your project is more than just steel and specifications; it’s a critical component of your operations, product, or infrastructure. From the very first meeting to final delivery, we prioritize transparency, open communication, and proactive problem-solving to keep your project on track and stress-free.

What this means for you:

Clear timelines and realistic expectations

Responsive communication and dedicated support

Flexibility to adapt to changing needs

A team that listens, collaborates, and delivers

We treat every project, big or small, with the same level of care and urgency as if it were our own.

2. End-to-End Capabilities

Unlike many shops that specialize in only one area, MAF provides a full spectrum of metal fabrication and machining services under one roof. From design and prototyping to machining, welding, and finishing, we handle every aspect of your project with total accountability and efficiency.

Benefits of our turnkey solutions:

Shorter lead times

Fewer vendors and handoffs

Greater quality control

Seamless project management

Reduced costs through efficiency

Whether you’re starting from scratch or need a partner to finish what you’ve started, we have the tools and talent to step in at any stage.

3. Precision Engineering with Real-World Application

Our team isn’t just technically skilled, we’re strategically insightful. We bridge the gap between engineering theory and practical application by designing solutions that perform reliably in the real world. Whether it's structural steel for construction, a machined part for an agricultural system, or a custom enclosure for electronics, we think through how the final product will be used, maintained, and integrated into your operation.

This results in:

Designs that optimize strength without waste

Machining tolerances that meet real performance needs

Components that integrate smoothly with your systems

Fewer revisions and more consistent performance

We don’t just build what’s on paper, we build what works.

4. Skilled Craftsmen with a Passion for Excellence

Our workforce is our greatest asset. At MAF, we’ve built a team of highly skilled welders, fabricators, machinists, engineers, and project managers who take pride in their craft. Every weld, cut, and contour is executed with attention to detail and a commitment to quality that shows in the final result.

What sets our team apart:

Certified welders and machinists

Decades of combined industry experience

A culture of continuous improvement

Mentorship programs to train the next generation

A shared commitment to safety and precision

We don't cut corners, we build to last.

5. Industry Versatility

Our expertise extends across a wide range of sectors, giving us unique insights into the specific challenges and compliance needs of each. Whether you’re in agriculture, energy, construction, manufacturing, or technology, we speak your language and understand your goals.

Industries we serve include:

Agricultural equipment and storage systems

Structural steel for commercial and residential construction

Oil and gas infrastructure and safety components

Material handling and conveyor systems

Custom industrial enclosures and machine parts

Architectural elements and public infrastructure

Because we serve such a broad client base, we bring cross-industry innovation to every job.

6. Commitment to Innovation and Technology

Technology is a core part of how we maintain our edge. We continuously invest in the latest tools, software, and equipment to streamline operations, improve accuracy, and increase production capacity.

Our facility features:

Advanced CNC machinery

Automated cutting and forming systems

3D CAD/CAM software for faster design iterations

Quality assurance systems with digital measuring tools

Ongoing equipment upgrades for greater efficiency

Our innovation isn’t just for show, it’s the engine behind faster turnaround times, tighter tolerances, and better results.

7. Uncompromising Quality Standards

MAF is known for delivering consistent quality that meets or exceeds industry expectations. Every step in our process is backed by rigorous checks, in-house testing, and thorough documentation. We hold ourselves to the highest standards because our clients do too.

Our quality approach includes:

ISO-compliant processes and documentation

Comprehensive inspection and testing protocols

Material certifications and traceability

Custom quality control plans for regulated industries

Commitment to zero-defect manufacturing

We don’t just aim for “good enough”, we aim for perfect.

8. Local Roots, National Reach

Based in Canada, MAF Metal Alloy Fabrication has strong ties to the local economy while servicing clients across the country. Our reputation for excellence and reliability has helped us expand into new regions and sectors, all while maintaining the close-knit values of a family-owned business.

Our footprint includes:

Local projects for municipalities and builders

Regional partnerships with industrial clients

Cross-border shipments for national manufacturers

Growing presence in Western Canada’s resource sector

No matter where you're located, MAF is ready to be your trusted fabrication partner.

9. Long-Term Relationships Built on Trust

We don't just want to win your business, we want to earn your trust. Many of our clients have been with us for years, returning again and again for new projects, repeat orders, or custom problem-solving. That’s because we prioritize relationships over transactions.

Our approach to partnership:

Transparent pricing and timelines

No hidden fees or last-minute surprises

Responsive customer service and status updates

Ongoing support beyond the project

Honest communication at every stage

When you work with MAF, you’re not just a customer, you’re part of the team.

Conclusion

At MAF, fabrication is just the beginning. From your first call to the final delivery, and long after, we’re focused on building real, measurable value for your operation. Our process ensures clarity and consistency, while our team’s craftsmanship, flexibility, and integrity elevate every project we touch.

No matter the size, scope, or complexity of your fabrication needs, we’re ready to bring your vision to life with the expertise, care, and performance you deserve. That’s the MAF Difference, and it’s why so many clients trust us as their long-term metal fabrication partner.