From Blueprint to Build: The Journey of Custom Metal Fabrication

- administrator6325

- May 30, 2025

- 6 min read

Updated: Jun 6, 2025

Every custom metal fabrication project begins with an idea, a need, a vision, or a challenge that calls for a durable, high-performance solution. At MAF Metal Alloy Fabrication, we specialize in transforming those ideas into reality through a comprehensive, end-to-end approach that combines innovation, precision, and decades of experience. From the moment a concept is introduced to the final product leaving our shop, our process is built to deliver excellence at every stage.

How Your Concepts Become Reality Through Expert Custom Fabrication Services

In this blog, we take you behind the scenes of that journey, from the first sketch to the final install, showcasing the care, collaboration, and craftsmanship that make MAF a trusted partner for clients across Western Canada.

Whether you're designing a complex industrial assembly, a sleek architectural element, or a custom agricultural component, our process ensures your project is built right the first time. Let’s explore how our team brings concepts to life, one expertly crafted piece at a time.

But beyond just the technical execution, we believe in forging strong relationships with our clients, built on trust, communication, and a shared vision of excellence. Every project is an opportunity to not only build something meaningful but also to demonstrate the values that define our work ethic: accountability, quality, and innovation. With every challenge we take on, we strive to exceed expectations and set new benchmarks in custom fabrication.

Understanding Goals & Project Scope

The journey starts with understanding. During the discovery and consultation phase, we take the time to listen closely to your needs, project goals, and functional requirements. Whether you're an engineer with precise technical specs or a business owner with a vision, our team is equipped to translate ideas into actionable plans. We begin by identifying the scope, intended use, materials needed, and budgetary constraints. This phase is all about collaboration, working together to align expectations and establish a clear roadmap for what’s ahead.

But it doesn’t stop at gathering information. We also analyze any initial drawings or concepts you provide, ask questions to identify potential design challenges early, and explore creative solutions that enhance performance, reduce costs, or improve manufacturability. Our deep industry knowledge allows us to advise on best practices, fabrication feasibility, and lead times. This proactive partnership ensures we’re not just making what you ask for, we’re helping you make it better.

Design & Engineering

Once the project requirements are defined, our design and engineering teams step in to bring the vision to life digitally. Using advanced CAD (Computer-Aided Design) and 3D modelling software, we create highly detailed renderings that form the foundation of every successful fabrication. These digital models give our clients a clear visual of the finished product while allowing us to make real-time adjustments based on feedback, tolerance requirements, or evolving specifications.

But design is about more than just drawings, it’s about solving problems before they occur. During this phase, our engineers evaluate stress points, load capacities, material thicknesses, and compatibility with other system components. We ensure that each design not only looks good on paper but is fully optimized for fabrication, assembly, and long-term performance. Our collaborative review process encourages client feedback, ensuring everyone is aligned before the next stage begins. This attention to detail on the front end minimizes delays and rework, ensuring a smoother, faster production timeline.

Material Selection & Planning

With designs finalized, we move into the material selection and planning phase. Choosing the right material is critical to the success of any fabrication project. Our team evaluates factors such as strength, durability, corrosion resistance, appearance, weight, and cost to ensure the best match for your application. Whether it's stainless steel for food-grade environments, aluminum for lightweight builds, or carbon steel for heavy-duty performance, we source only high-quality metals from trusted suppliers.

But material selection is only one part of this stage. We also develop a complete fabrication plan that includes cutting paths, part nesting, machine programming, and scheduling. Every detail is considered to optimize production efficiency and reduce material waste. Our in-house planning software allows us to simulate the full fabrication process before a single cut is made, ensuring precision, minimizing error, and staying on track with project deadlines. This phase sets the stage for a seamless transition from planning to production.

Cutting & Shaping

With a detailed plan in hand, we move into fabrication, starting with cutting and shaping the raw materials. At MAF, we offer both laser cutting and water jet cutting capabilities to meet the demands of a wide range of projects. Laser cutting delivers ultra-precise, clean cuts ideal for intricate geometries, while water jet cutting offers flexibility for thicker or heat-sensitive materials.

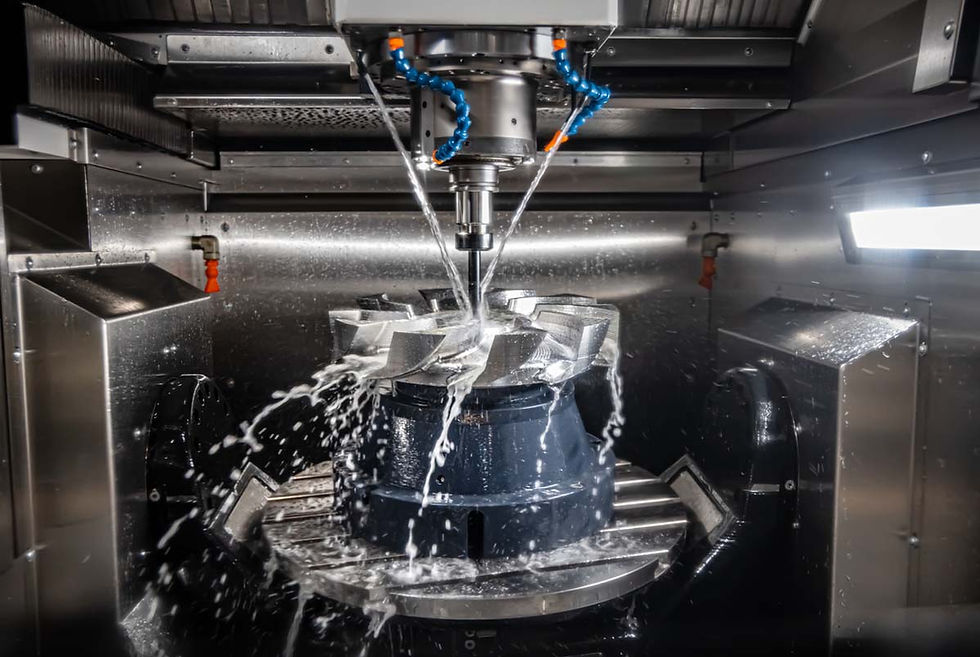

Each method is programmed and controlled by skilled operators using advanced CNC (Computer Numerical Control) machines to ensure exact tolerances and repeatable results. Our cutting equipment is regularly calibrated and maintained for peak performance, and our team monitors each job to maintain the highest quality standards.

Beyond cutting, we offer precision bending, rolling, and machining to give each part its required shape. These forming processes are carefully controlled to preserve structural integrity and maintain tight dimensional tolerances. From curved panels to multi-angled frames, every component is crafted to fit and function exactly as intended. Our investment in advanced equipment ensures we can meet even the most complex fabrication requirements with confidence.

Assembly, Welding & Finishing

Once individual components are cut and shaped, they move to the assembly and welding stage. This is where your project truly starts to take form. Our certified welders use a range of techniques, including MIG, TIG, and stick welding, based on the material type, structural requirements, and desired finish. Each weld is executed with precision and inspected for strength, appearance, and consistency.

Assembly is equally meticulous. Our team uses detailed fabrication drawings to position and secure each component in place, checking alignment, squareness, and fit throughout the process. For complex builds, we may use jigs or fixtures to ensure consistency across multiple units. Our attention to detail at this stage helps eliminate surprises down the line.

To finish the job, we offer deburring, brushing, and polishing services that enhance both function and appearance. Whether it’s smoothing sharp edges, removing surface imperfections, or giving a clean, uniform finish, our finishing team ensures every part looks as good as it performs. If required, we can also coordinate powder coating, galvanizing, or other specialized finishes through our trusted network of partners.

Inspection, Delivery & Installation

Before any product leaves our shop, it undergoes a thorough inspection process. We verify that every part meets your specifications for dimensions, weld integrity, surface finish, and overall quality. This final checkpoint reflects our commitment to excellence and gives our clients confidence that what they receive is ready for service.

But our job doesn’t stop at inspection. We also provide packaging, delivery, and installation support depending on project requirements. Our logistics team ensures that parts are securely packaged to prevent damage in transit and delivered on schedule. For clients who require installation, we offer professional on-site services to ensure proper assembly, alignment, and functionality, ensuring your product performs exactly as designed in its final environment.

From simple shipments to turnkey installations, our end-to-end support helps ensure that every project concludes with success. We treat your deadline as our own and your satisfaction as our standard.

Why Clients Trust MAF

At MAF Metal Alloy Fabrication, our strength lies not only in our process but also in our people. With decades of experience across multiple industries, our team is passionate about quality and driven by results. We invest in state-of-the-art equipment and continuous training to stay ahead of evolving industry demands, and we pride ourselves on transparency, collaboration, and integrity in every project we take on.

Clients choose MAF because they know we deliver on time, on budget, and to exacting standards. Whether it’s a short-run custom build or a high-volume production order, we bring the same level of care and expertise to every job. It’s this commitment that has earned us the trust of partners across Western Canada and beyond.

Our commitment doesn’t stop when the job is done. We believe in long-term partnerships, supporting our clients well after delivery through technical advice, design revisions, and future project planning. This relationship-first approach fosters loyalty, mutual respect, and consistent results that stand the test of time. At MAF, your success is our success, and we work tirelessly to earn and maintain your trust every step of the way.

Conclusion: From Vision to Completion

The journey of custom metal fabrication is complex, but with the right partner, it doesn’t have to be difficult. At MAF Metal Alloy Fabrication, we’ve built our reputation on guiding clients through every phase with clarity, precision, and pride. From the first spark of an idea to the final bolt tightened on-site, we’re here to turn vision into value.

Have a project in mind? Contact us today to start your fabrication journey with a team that’s built to deliver.

We welcome the opportunity to tackle new challenges and deliver solutions that go beyond expectations. Whether you’re in the early design stage or ready for production, MAF is ready to be the partner you can count on. Our hands-on, collaborative approach ensures every step of the process runs smoothly, from idea to implementation. Reach out and discover how our commitment to quality and customer service can make a measurable difference in your next project.