Exploring Laser Cutting Services at MAF Metal Alloy Fabrication

- administrator6325

- Jun 19, 2025

- 8 min read

At MAF Metal Alloy Fabrication, precision isn’t a buzzword; it’s a promise. And nowhere is that promise more clearly delivered than in our laser cutting services. As one of the most advanced and reliable fabrication technologies in use today, laser cutting plays a central role in the production of high-performance parts, architectural components, and custom builds. From flawless signage to intricately detailed industrial parts, laser cutting enables us to produce consistent, exact results every time.

In this blog, we take a deep dive into the laser cutting division at MAF. We’ll explain what laser cutting is, how it works, the types of materials we handle, the benefits for your business, and why clients across Western Canada trust MAF for laser cutting solutions that go beyond the ordinary.

What Is Laser Cutting? Understanding the Precision Process Behind Every Cut

Laser cutting is a fabrication process that uses a concentrated beam of light, known as a laser, to cut through various materials with incredible precision. At MAF Metal Alloy Fabrication, this technology is central to our operations, allowing us to achieve intricate, high-tolerance cuts on metal components for a range of industries, from architectural detailing to industrial manufacturing.

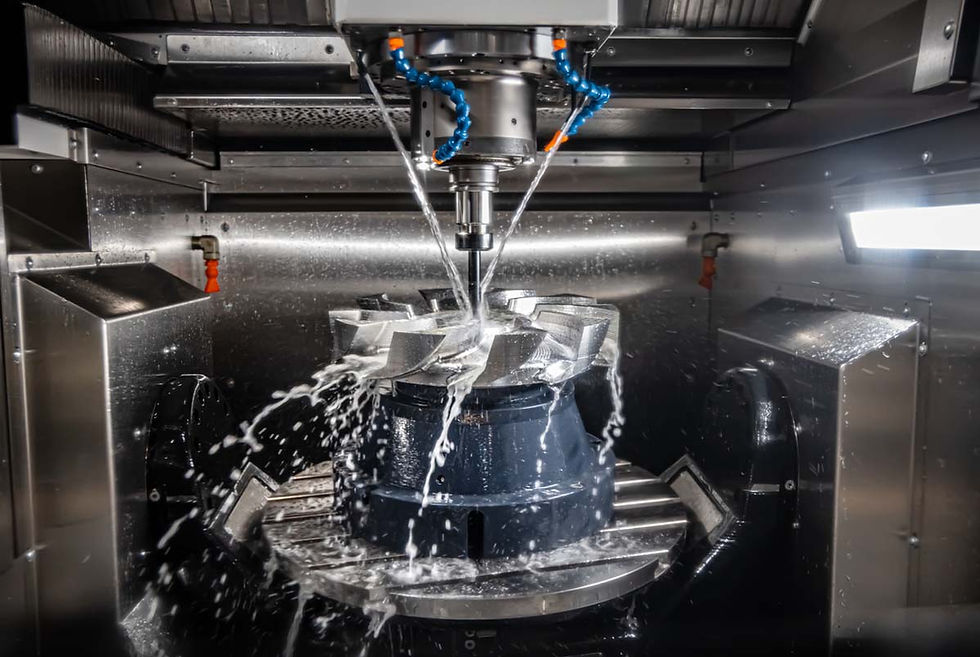

Unlike traditional cutting methods that rely on physical force or mechanical tools, laser cutting is a non-contact process. This means there’s minimal wear and tear on tools, less deformation of the material, and a significantly cleaner finish. The laser beam is directed by CNC (Computer Numerical Control) programming, which enables extremely accurate replication of complex designs and geometries with minimal error, even on thin or detailed components.

The process begins when a high-powered laser is focused on a specific point on the material. As the energy from the laser is absorbed, it melts or vaporizes the metal, leaving a sharp, clean edge. The surrounding material remains untouched, preserving the structural integrity of the piece. With the addition of assist gases like nitrogen or oxygen, we can enhance the cutting speed and finish depending on the type of metal being used.

At MAF, our laser cutting technology is equipped to handle a wide range of materials, including stainless steel, carbon steel, and aluminum. This versatility allows us to serve a broad array of applications, whether it’s industrial parts, artistic installations, signage, or architectural cladding.

But laser cutting isn’t just about removing material; it’s about setting a standard. When it comes to efficiency, detail, and consistency, there is no better tool for shaping metal. The speed and automation that come with this process not only reduce production times but also lower overall costs, making it ideal for both high-volume runs and one-of-a-kind custom projects.

Our Laser Cutting Capabilities at MAF

MAF's in-house laser cutting facility is equipped with advanced fibre laser machines capable of handling a wide range of metals and thicknesses. We work with:

Stainless Steel

Aluminum

Mild Steel / Carbon Steel

Copper and Brass

Galvanized and Coated Metals

We routinely process sheets ranging from 22 gauge to over 1 inch in thickness, depending on the material. Whether you’re prototyping a new product, designing a custom sign, or commissioning a public art installation, we deliver precision and consistency from the first cut to the last.

Why Precision Matters in Fabrication

Precision is the backbone of successful metal fabrication. Whether you're constructing structural elements for a commercial development or creating ornamental panels for a branded environment, accuracy is not optional; it’s essential. Every millimetre matters, especially when parts must align perfectly, support weight, or convey a consistent brand image.

Inconsistent or imprecise cuts can lead to material waste, misalignments, structural issues, and costly delays in assembly. Worse yet, it can result in the failure of the end product to meet performance or aesthetic expectations. That’s why precision is more than a buzzword at MAF; it’s a guarantee.

Our laser cutting systems are calibrated to extremely tight tolerances, ensuring that every component we produce matches the design exactly. This level of accuracy is particularly important for projects with interlocking components, decorative details, or brand elements like logos, typography, or dimensional signage. Even minor deviations can disrupt the flow of a design or render components incompatible with their intended purpose.

Precision in fabrication also affects long-term durability and usability. Smooth, accurate cuts eliminate stress points that could lead to fatigue or corrosion over time. Clean edges reduce the need for additional grinding or finishing, allowing for faster production and cleaner assembly. For industries like architecture, hospitality, or retail, where form is as important as function, precision enables elevated design execution that leaves a lasting impression.

But precision isn’t just about machines, it’s about people. At MAF, our experienced technicians and operators carefully monitor every cut, inspect output regularly, and maintain meticulous quality control throughout the process. This human oversight, combined with our investment in advanced equipment, means every project benefits from craftsmanship you can trust.

Real-World Applications of Laser Cutting

Branded Architectural Metalwork

In Calgary’s growing market for branded environments, businesses rely on custom architectural features to distinguish their spaces. Laser-cut wall panels, branded signage, logo cutouts, and ceiling features all add texture, character, and meaning to a space. These elements tell your story, not just visually, but structurally, and MAF is a trusted partner in making that story tangible.

Public Art & Civic Installations

Precision matters in artistic expression, too. MAF has partnered with artists, Indigenous creators, and municipalities to produce laser-cut panels that are both symbolic and enduring. From geometric patterns to culturally significant illustrations, our laser work has become part of Calgary’s streetscapes and gathering spaces.

Industrial & Agricultural Equipment

For industries that demand performance, laser cutting provides the accuracy and repeatability needed for durable machinery. Whether it's precision brackets, mounting plates, guards, or framework components, MAF delivers parts that stand up to wear, stress, and the environment.

Step-by-Step: How Laser Cutting Works at MAF

1. Project Intake

Every laser cutting project starts with collaboration. You bring us a design, a concept, or a performance goal, and our team helps transform that into a file that can be cut with precision. We accept industry-standard vector files (.DXF, .DWG) or help generate them in-house if needed.

2. Material Selection

Choosing the right material is critical. We’ll consult with you on strength, corrosion resistance, weight, and finish to select the best match for your use case. Our broad inventory ensures quick turnaround and flexibility.

3. Nesting and Programming

Using advanced nesting software, we optimize the layout of your parts to reduce waste and improve cutting efficiency. Once the layout is set, we program the machine and run a test simulation to verify accuracy.

4. Laser Cutting Execution

Our CNC fibre laser systems are then put to work. The beam is guided over the metal with incredible speed and accuracy, making cuts as narrow as a hairline and as intricate as a signature.

5. Finishing (Optional)

Once your pieces are cut, they can be finished according to your needs, deburring, polishing, powder coating, or integration into larger welded assemblies.

Benefits of Laser Cutting at MAF

Clean, Professional Results

Laser cutting produces crisp lines and tight curves, which elevates the quality of any finished product. It's ideal for customer-facing pieces where aesthetics are just as important as function.

High-Speed Turnaround

Because there are no tool changes or manual adjustments between cuts, laser cutting is much faster than traditional methods, especially for high-volume orders or intricate designs.

Reduced Material Waste

Our cutting software minimizes offcuts and maximizes yield. That means less scrap, lower material costs, and a more sustainable approach to fabrication.

Flexible Quantities

Whether you need one prototype or a thousand parts, laser cutting is scalable. It’s perfect for everything from testing a concept to fulfilling large production runs.

Supporting Calgary’s Creative and Industrial Communities

MAF's laser cutting shop supports a wide range of creators and industries in Calgary and across Western Canada. Our clients include:

Architects & Interior Designers

Commercial Developers

Municipal Governments

Indigenous Artists & Cultural Creators

Oil & Gas Contractors

Farm Equipment Manufacturers

With each collaboration, we bring craftsmanship, efficiency, and adaptability to the table.

Customization at Its Best: Telling Your Brand Story

At MAF, we know that every business has a story, and our laser cutting team helps you tell it. Whether through metal signage, sculptural installations, or branded wall panels, we create elements that become signature pieces of your space.

Think of a downtown restaurant with a backlit, laser-cut logo. Or a corporate office with an abstract laser-cut pattern on its boardroom wall that ties into its brand identity. These aren’t just design choices, they're statements about who you are. MAF helps make those statements bold, intentional, and built to last.

Integration with Other MAF Services

Laser cutting is just one chapter of the story. At MAF, we offer full-service fabrication under one roof, including:

Welding & Assembly

CNC Machining

Bending & Forming

Custom Design Support

Installation Services

This means tighter project timelines, fewer vendors, and more control over your final outcome. When laser cutting is part of a larger build, our seamless integration ensures every piece fits perfectly.

Quality You Can Count On

Quality at MAF Metal Alloy Fabrication isn’t just an outcome; it’s a mindset woven into every step of our laser cutting process. From initial consultation to the final inspection, we operate under the principle that the smallest details yield the biggest results. Our commitment to quality control ensures that every cut, every edge, and every curve meets the high standards we’re known for.

What sets our laser cutting services apart is not only the precision of our machines but the rigour of our internal processes. Every file goes through a multi-layer review, including material analysis, cut path simulation, and prototype testing when required. This means your designs are not only accurately cut but also evaluated for structural integrity, manufacturability, and long-term performance.

Our facility is equipped with state-of-the-art laser systems capable of cutting through a range of metals at varying thicknesses. Whether we’re working with thick industrial-grade steel or fine aluminum sheets for decorative features, the result is always clean, crisp, and consistent. Even with high-volume orders, we maintain tight tolerances and visual uniformity across all units.

We also understand that quality extends beyond the physical product; it includes on-time delivery, transparent communication, and reliable project execution. Our streamlined production workflow, experienced staff, and strategic sourcing all contribute to meeting deadlines without compromising quality.

For clients in industries like architecture, commercial construction, and branded environments, the finished product is often a visible, defining part of the space. That’s why our reputation is built on producing not just functional components, but showpiece-quality results that elevate your entire project.

When you choose MAF for laser cutting, you’re not just getting access to top-tier equipment; you’re gaining a partner committed to excellence in every cut.

Why Choose MAF for Laser Cutting?

Local Expertise: Based in Calgary and serving Western Canada with pride.

Advanced Equipment: We invest in cutting-edge technology for better results.

Flexible Projects: From one-off pieces to production-scale runs.

Collaborative Service: We work closely with clients at every stage.

High Standards: Quality assurance is built into every job.

Conclusion: Sharp Results, Strong Partnerships

Laser cutting is more than just a way to shape metal; it’s a way to shape ideas into reality. At MAF Metal Alloy Fabrication, our precision cutting services give your projects the accuracy, speed, and aesthetic finish they deserve.

Whether you're building a brand, producing functional parts, or bringing art to life, MAF is your trusted partner in precision fabrication. Let’s create something remarkable—one cut at a time.

Ready to get started? Contact us today to learn more about our laser cutting services and discover how MAF can help you achieve precision, beauty, and performance in every piece.